Woven poly bag (also called woven pp bags) are generally large sacks made out of woven polypropylene or PP. They can be printed on directly using Flexo Printing technology, or laminated with an additional and slightly different type of polypropylene film that allows for the utilization of Rotogravure Printing which yields ultra bright colors and vivid full color images.

Because it is woven plastic, it is known to be much stronger and sturdier than a paper bag and far less expensive than a laminated bag.

There are three main types/uses of woven poly bags that one is likely to encounter:

1. Product Packaging – These are side gusseted bags used for dry bulk foods such as rice, beans, grains, seeds, pet foods etc. to be sold on retail shelves.

2. Tote Style – often sold by grocery stores as a reusable grocery bag.

3. Massive Bulk Bags – used for wholesale business to business selling and not for retail.

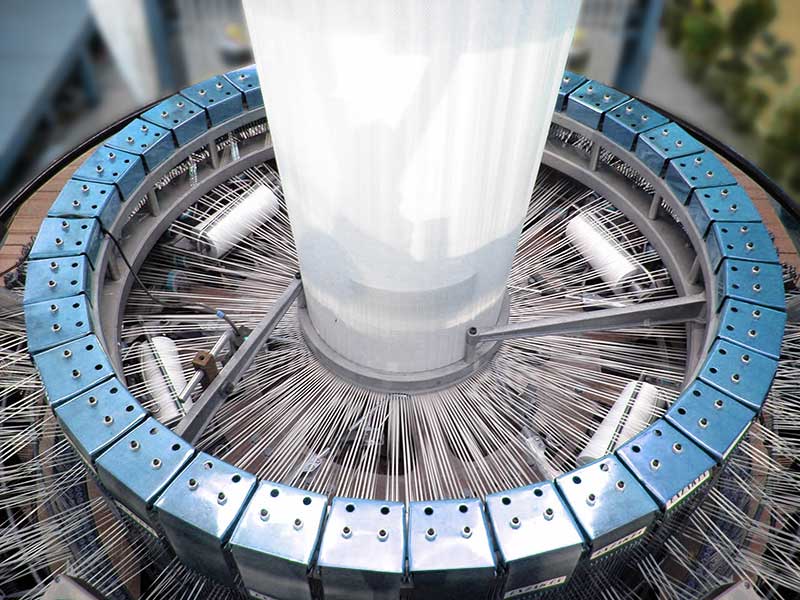

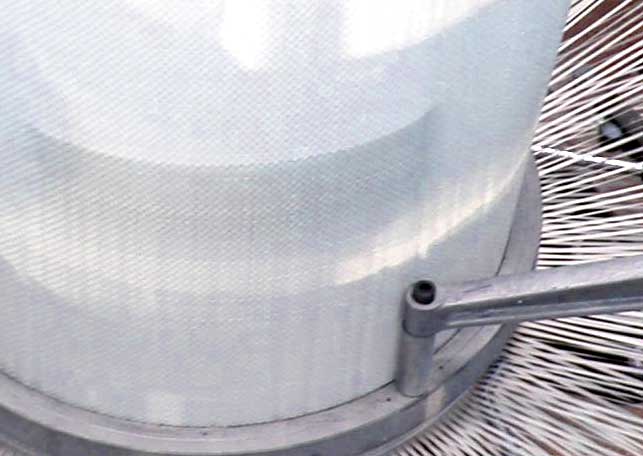

How Are These Bags Made?

So, Why Are Woven Poly Bags So Awesome?

4 Reasons:

Reason 1

Aesthetically pleasing and able to display gorgeous graphics and vivid full color images

Reason 2

Extremely durable and strong. These bags simply do not tear (at least not without serious, serious abuse!).

Reason 3

Ultra economical (and of course, the more you buy, the cheaper it gets)

Reason 4

Most Are Recyclable (except for “Paper Laminated Woven Poly Bags”)

There is no doubt as to why this packaging technology is so ideal for its uses. And there are new technologies on the horizon that are going to make these types of bags even more desirable. How about a “heat seal” enclosure instead of the usual “sewn seal”? For people in the know, this is an exciting development.

This has been a part of my tutorial series called How to Buy Packaging 101. So click the link below to head back if you haven’t finished reading it yet. 🙂

4 Responses

SARA, THE PACKAGING I NEED ONLY NEEDS TO HOLD 5 TO 10 SEEDS ABOUT THE SIZE OF ORANGE SEEDS. I PROBABLY NEED SOME KIND OF ENVELOPE. CAN YOU HELP ME?

Hi Norma, there are companies who specialize in envelopes for seeds – please look through a directory formed by a “seed association” or trade show company – they may list some of their members on their website.

Hi Sara,

Thanks for the great content. If I am using this bulk poly bags for fried food (such as fried beans), do you suggest I use a thin layer bag inside? Appreciate your help!

Hi Sue, it will depend on your product’s needs. If your product is senitive to moisture or air, then it may require an additional layer or barrier of protection. The woven poly bag already has 2 layers, if its dried rice for example, there is no need for the inner poly. It will also depend on how long your product is expected to last within the 2 ply woven bag, if its 6-8 months then you won’t need another liner, but if its longer, you may need the additional protection.