The packaging industry is truly fascinating, but it can get complicated. How a box is made, or manufactured, requires many steps to ensure quality and accuracy. It can be costly to make a printed custom box and many precautions are initiated to avoid mistakes.

Let’s take a look at how a box is made from beginning to end.

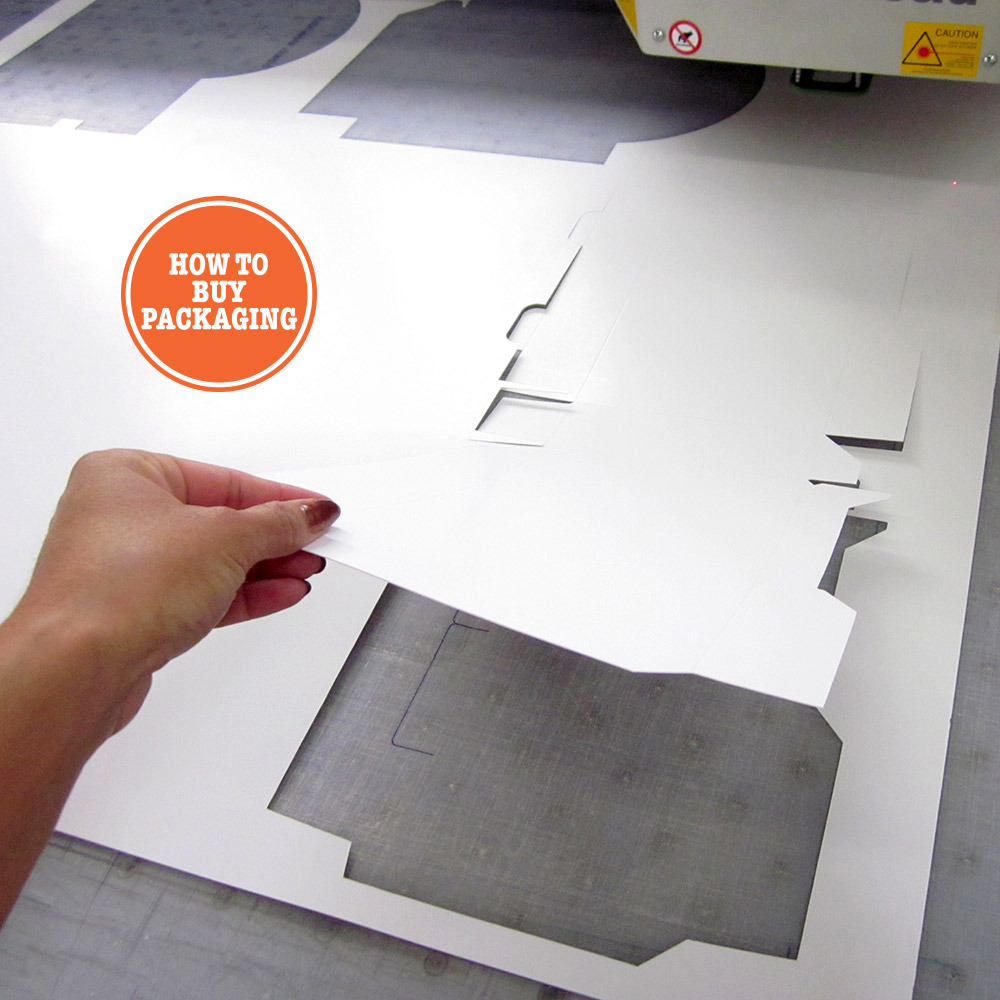

1st Stage – Structural Design

A box designer/engineer will hand-build the box to fit your product.

This process may be repeated several times before the client settles on the right box for their product

2nd Stage – Pre-Production

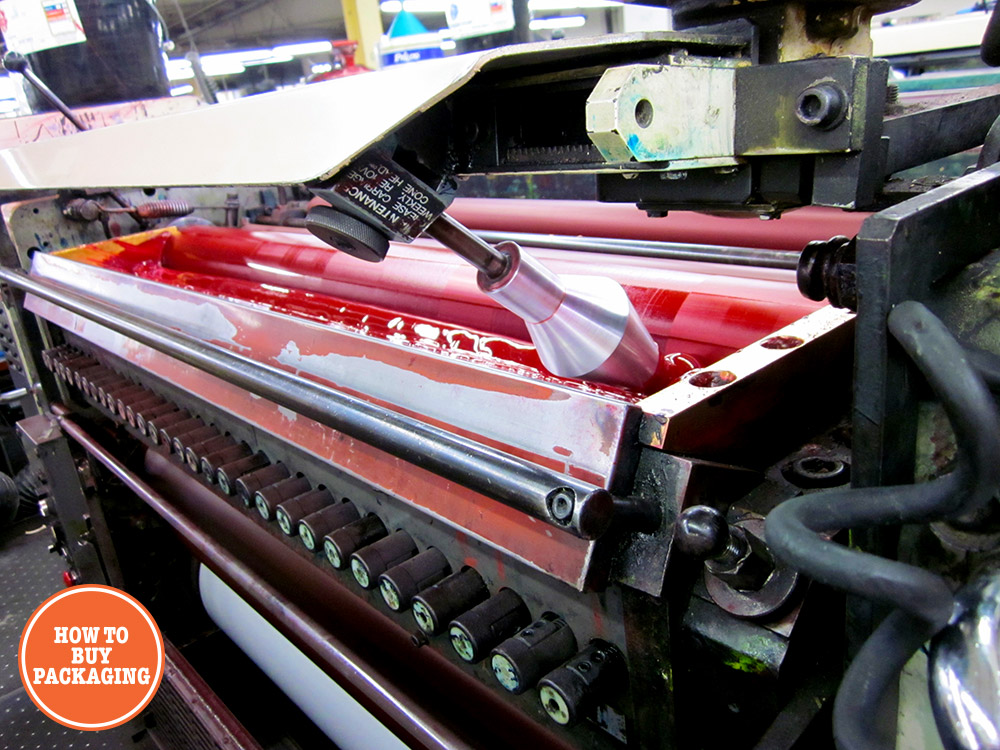

3rd Stage – Production Time

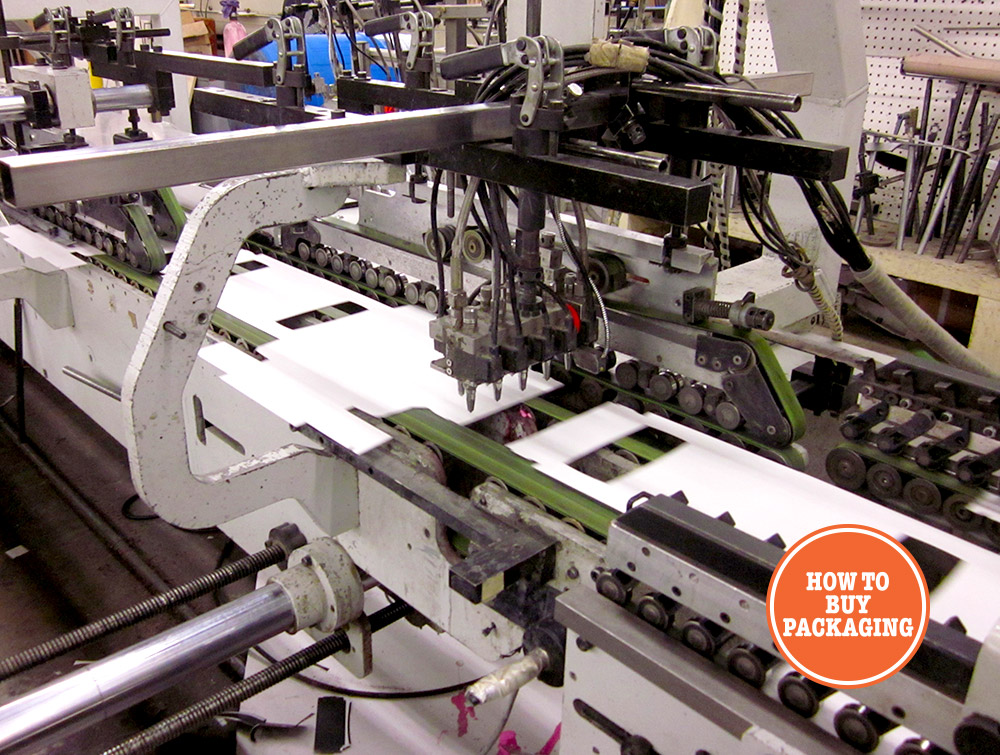

4th Stage – Post Production

And that, in a nutshell, is how a box is made.

This has been a part of my tutorial series called How to Buy Packaging 101. So click the link below to head back if you haven’t finished reading it yet. 🙂