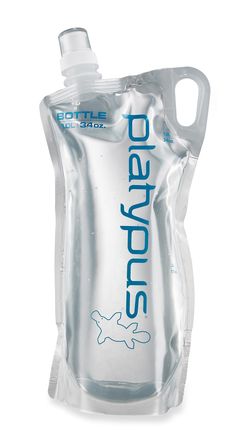

We are seeing flexible packaging, commonly referred to as stand-up pouches (although the term “flexible packaging” encompasses a larger array of bag-type packaging), more and more on retail shelves, hosting an ever growing diversity of products. There are many reasons for this trend, reasons that suggest this is, perhaps, much more than a trend.

We are seeing flexible packaging used for dry goods, liquids, electronics, cosmetics, cleaning products, frozen foods, etc.

Flexible Packaging is Lighter and Uses Less Raw Materials

Excellent Barrier Protection (And I Mean Excellent!)

Flexible packaging can have barrier protection almost as impervious as glass. This keeps products safer and fresher. And what’s even better is that flexible packaging’s barrier protection can be customized for whatever the product demands. If the product requires an impenetrable barrier against light, moisture and oxygen, or if a modest to trivial amount of protective barrier is all that is needed, the flexible packaging can be designed accordingly. There’s no need for any unnecessary “over packaging”.

Beautiful High End Graphics Capabilities

Printing on flexible packaging can be absolutely gorgeous and unparalleled. The graphics are generally brighter and shinier than most other printed packaging. However, it does depend on which type of printing the bag manufacturer uses.

There are two main types of printing when it come to flexible packaging (stand-up pouches):

FLEXO (Full name is: FLEXOGRAPHIC)

GRAVURE (Full name is: ROTOGRAVURE)

These types of printing processes can be discussed at length, but the important things to understand from a buyer’s point of view is that:

Gravure printing is a newer technology. The colors are more vibrant and it has the ability to do very thin lines, vignettes and silhouettes which flexo cannot do well or at all.

Flexo is an older technology. The colors tend to be more washed out and less vibrant.

In a nutshell, Gravure printing has slower turnarounds and higher quality, while flexo is generally quicker but with average quality.

So, when comparing vendors, the differences in the printing processes is important to understand.

Ease of Use = Greater Customer Experience

Easy to Tear Open – using laser scored tear areas translates to no more customer frustration.

Easy to Seal – using zipper enclosure, fitment caps, or even the new “velcro” style). The product stays fresher longer.

Easy to Dispense – some larger bags have handles on their bottoms for two-handed pouring.

And, depending on the product, increased yield (which means you get more of the product out of the packaging, think salad dressing in a flexible packaging that you can squeeze like a toothpaste tube vs a jar or plastic container).

Pre-Printed Bags Require No Extra Step Affixing a Label

Flexible Packaging Can Be Made to Fit Virtually Any Product Shape

Not only is shape a non issue for most bag manufacturers, but sizing options are vast as well. It’s much easier than ever before for flexible packaging manufacturers to create larger sizes for bulk buying (Costco anyone?) And people are more likely to buy in bulk when the packaging keeps the product fresher longer.

All the Bells and Whistles of Other Packaging Types

Flexible packaging can, of course, have foil effects, embossing, clear windows, matt finish, glossy finish and just about anything else you can think of that other packaging types use to garner customer attention.

Flexible packaging is definitely one of the fastest growing segments of the packaging industry, and it is easy to see why. Maybe it’s time you considered switching to flexible packaging, everyone else seems to be.

This has been a part of my tutorial series called How to Buy Packaging 101. So click the link below to head back if you haven’t finished reading it yet. 🙂